There is no doubt that our modern radio control systems are a far cry from the first R/C units developed some 50years ago.

Now we have 2.4GHZ technology which is increasing in popularity on a daily basis, both here and around the world. However, as with all new technology, there are a few new things to learn and practices to adopt in order to correctly operate these new radio systems regardless of brand or type.

No longer can we wrap the receiver in some protective foam and place the receiver where it fits best. Whether your system has multiple receiver antennas or a single antenna, great care needs to be taken and the manufacturers instructions need to be followed accurately when installing the receiver, especially in regard to antenna positioning. For example our popular XPS 2.4GHZ system requires that the receiver be installed with all leads and metal objects kept 2” away from the receiver antenna. One item, that seems to be common with all 2.4GHZ systems, is that they all require a good constant power supply to the receiver, especially when using digital servos.

The connectors used for servos and batteries are ideally only suited to handling a few amps. To increase the current available to the receiver and servos, a second lead can be spliced into the receiver power supply lead from the switch harness and plugged into a spare receiver channel, effectively doubling the current that can be supplied to the receiver.

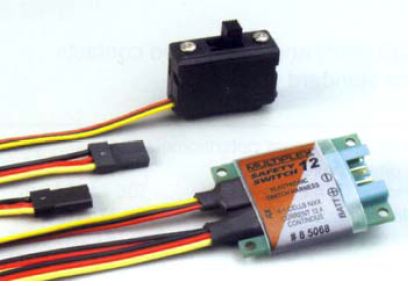

Another option is the use of a ’Safety Switch’ such as the Multiplex 12 amp unit. This has two power supply leads to the receiver and offers the added benefit of protection against a mechanical switch failure. Increase the size and capacity of the receiver pack. The old 600mah Ni-Cd packs that used to be supplied with radios a few years ago, are no longer good enough.

Even many of the 40 size sport models now have an extra one or two servos—dual aileron and elevator servos for example. A 5 cell 1800mah pack is now probably a better option.

Electric flyers should also remember that many BEC’s will only supply a maximum of 2 amps, (Some only just 1 amp! Phil L.) so a separate receiver battery should be considered.

Range checking of 2.4GHZ systems also requires a different approach and technique when compared to our 36MHZ systems. Most 2.4GHZ systems require the operator to push in a button on the transmitter module which reduces the output power.

The Multiplex 12 amp ‘Safety Switch’ has two power supply leads to the receiver and offers the added benefit of protection against a mechanical switch failure.

Code: MPX85068

Again the manufacturers instructions must be followed accurately if any potential issues are to be discovered. There are many advantages to be gained from 2.4GHZ technology, such as not having to wait for a specific frequency on a busy day at the field. For Contest Directors, it is a godsend as frequency clashes are a thing of the past, however to get the most out of this technology and all it has to offer, we just need to rethink and readjust the way we do things. Follow the manufacturers instructions explicitly on installation and range checking and keep a good power supply up to the receivers.

| Permission to reproduce this article has been obtained from Model Engines. It is from the March 2008 Edition of Model Engines News and it could be of interest to many P&DARCS members. The comments apply to all types and brands of 2.4Ghz equipment. |